Anomaly detection : condition-based and predictive maintenance

Anomaly detection : condition-based and predictive maintenance with Lesly

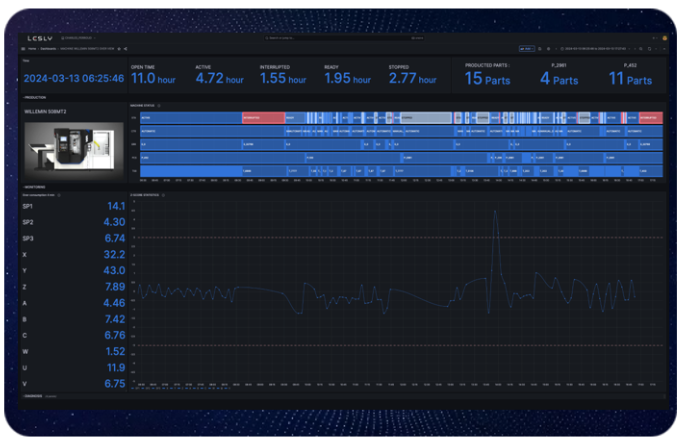

In an industrial environment where machines are subject to continuous stress, early detection of anomalies is essential to prevent breakdowns and guarantee availability. Lesly integrates two complementary solutions for condition-based maintenance, which monitors performance in real time, and predictive maintenance, which anticipates breakdowns thanks to AI.

Conditional maintenance: Real-time monitoring

Conditional maintenance is designed for cyclic, continuous-process machines. It is based on the use of an SPC (Statistical Process Control) control board, a powerful tool for real-time monitoring of performance and quality. This solution automatically detects anomalies, variations and drifts by comparing the data collected with predefined thresholds.

Highlights of condition-based maintenance with Lesly :

- Instant drift detection.

- Automatic alerts for rapid diagnosis.

- Process stabilization through targeted interventions.

- Precise detection: thanks to univariate tracking, each key parameter is monitored independently.

Predictive maintenance: Anticipating breakdowns

Lesly’s predictive maintenance goes one step further by integrating AI models. These models analyze multivariate data from variable-speed, multi-process machines to predict potential failures.

Benefits :

- Characterization of equipment status as soon as it is commissioned (Km0).

- Increased accuracy thanks to multivariate analysis.

- Estimation of residual equipment life for replacement planning.

Predictive or condition-based maintenance: Which solution to choose?

Condition-based maintenance

Perfect for cyclical and continuous processes where rapid detection of univariate anomalies is sufficient

Predictive Maintenance

ideal for more complex environments where machines operate at variable speeds and require multivariate analysis to predict failures.

Why adopt these solutions?

Whether you choose condition-based or predictive maintenance, these strategies offer considerable advantages for optimizing your processes and performance. They enable :

- Reduce downtime: Anticipating breakdowns reduces costly downtime.

- Reduced maintenance costs: Less corrective maintenance, more planned interventions.

- Improved machine availability: equipment is always in optimum operating condition.

- Enhanced safety: Fewer sudden failures, greater reliability.

- Extended equipment life.

- Improved productivity.

At Dianalyse, we offer customized solutions to meet your specific needs. Whether you need to set up SPC control cards or use Km0 models, we’re here to support you every step of the way.

Use Case: A metal components factory

In a metal parts production plant, Lesly has been deployed to monitor critical equipment. By combining condition-based and predictive maintenance, the results achieved include :

- A 15% reduction in maintenance costs thanks to better-targeted interventions.

- A 12% increase in machine availability in 6 months.

- An overall improvement in the quality of finished products.

Choose Lesly

With Lesly, anomaly detection is not limited to reaction: it becomes a strategic tool for anticipating, planning and optimizing. Whether you want to stabilize your processes or anticipate breakdowns, Lesly offers tailor-made solutions to meet your needs.

Do you have problems with machine downtime or process quality?

We'll help you solve your downtime problems.