Lesly is Your expert for low speed machines monitoring

Lesly AI gets you the best machining management for the best produced part, right from the beginning, without machine downtime.

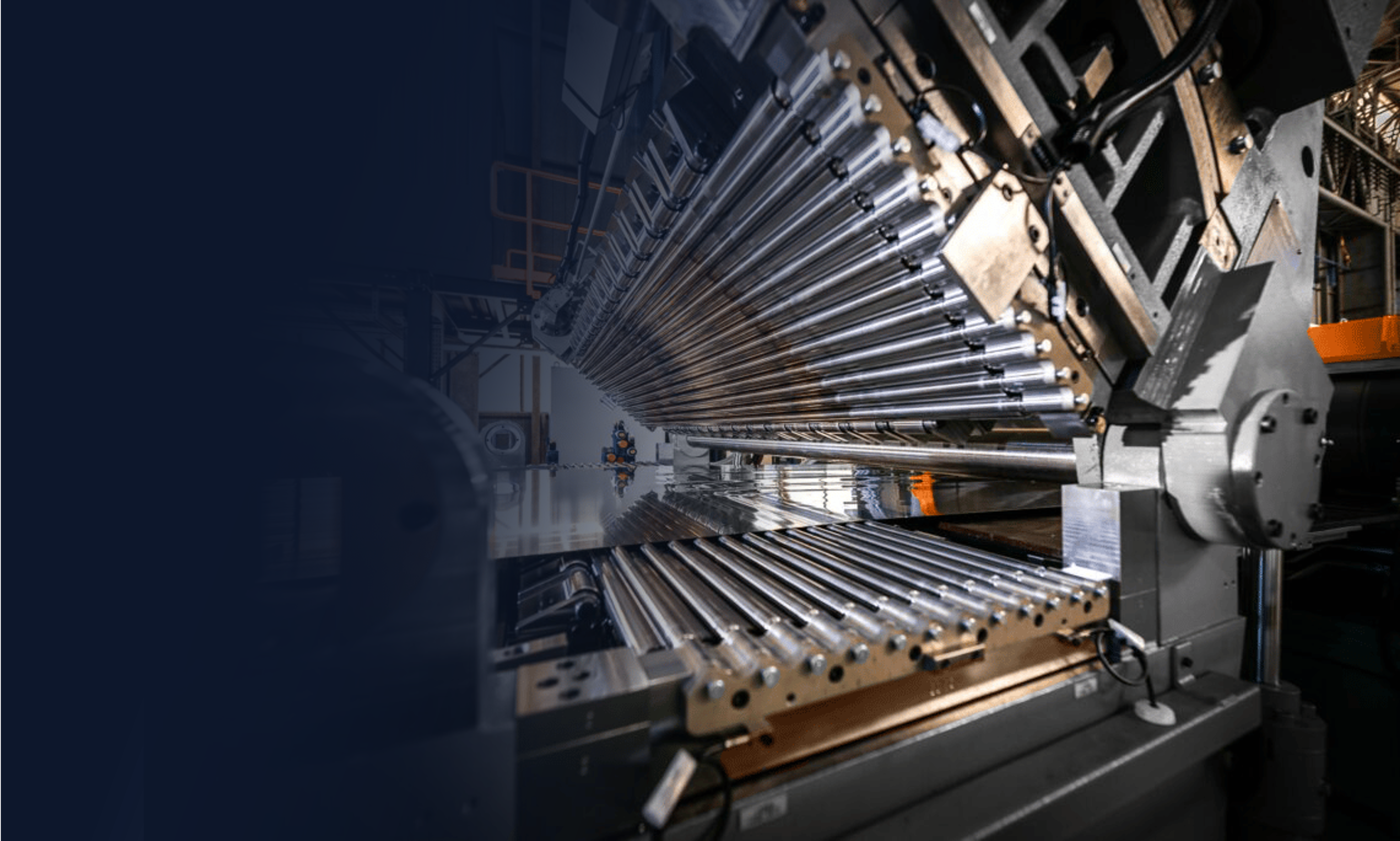

Low speed machines

At AptarPharma, Lesly used exclusively the data available in the PLC to highlight a belt tension loss defect on a vulcanization line running at 1 rpm. It also detected a slight belt tension loss defect. At SETIC Lesly was able to highlight unbalance faults on the rotation axis of a motor at 300 rpm.

Turn your low speed machines into intelligent self-diagnosis machines

The production line with low speed and variable speed machines, are broadly used within the manufacturing, pharmaceutical, metal and energy industries. Adding sensors is very difficult, and vibration sensors have their specific limits : no vibration with friction neither sliding phenomena.

Presses, Winding machines, Rolling mills, Conveyors, Robots, etc, are mostly low speed machines (< 500 rpm) with long continuous transformation/production processes. The main issues are the raw materials, the yield, and the productivity.

Lesly analyzes the available data in the PLC and characterizes the healthy references of each process and of mechanical component. It highlights the drifts by indicating the influencing parameters and estimating the residual lifetime : this is the concept of Km0. Lesly will allow to extend the lifespan of the wearing components, to avoid raw material losses and park machine downtime.

Collect Data From Any PLC

The Lesly software suite embeds all main machine protocols. Collecting data from PLC has never been so simple and easy !

Having machine downtime issues with a quality loss ?

Schedule Conf Call And We Will Help You !