Using AI to Predict Industrial Failures

In an era where competitiveness relies heavily on the reliability and responsiveness of equipment, using AI to predict industrial failures has become a strategic necessity.

In an era where competitiveness relies heavily on the reliability and responsiveness of equipment, using AI to predict industrial failures has become a strategic necessity.

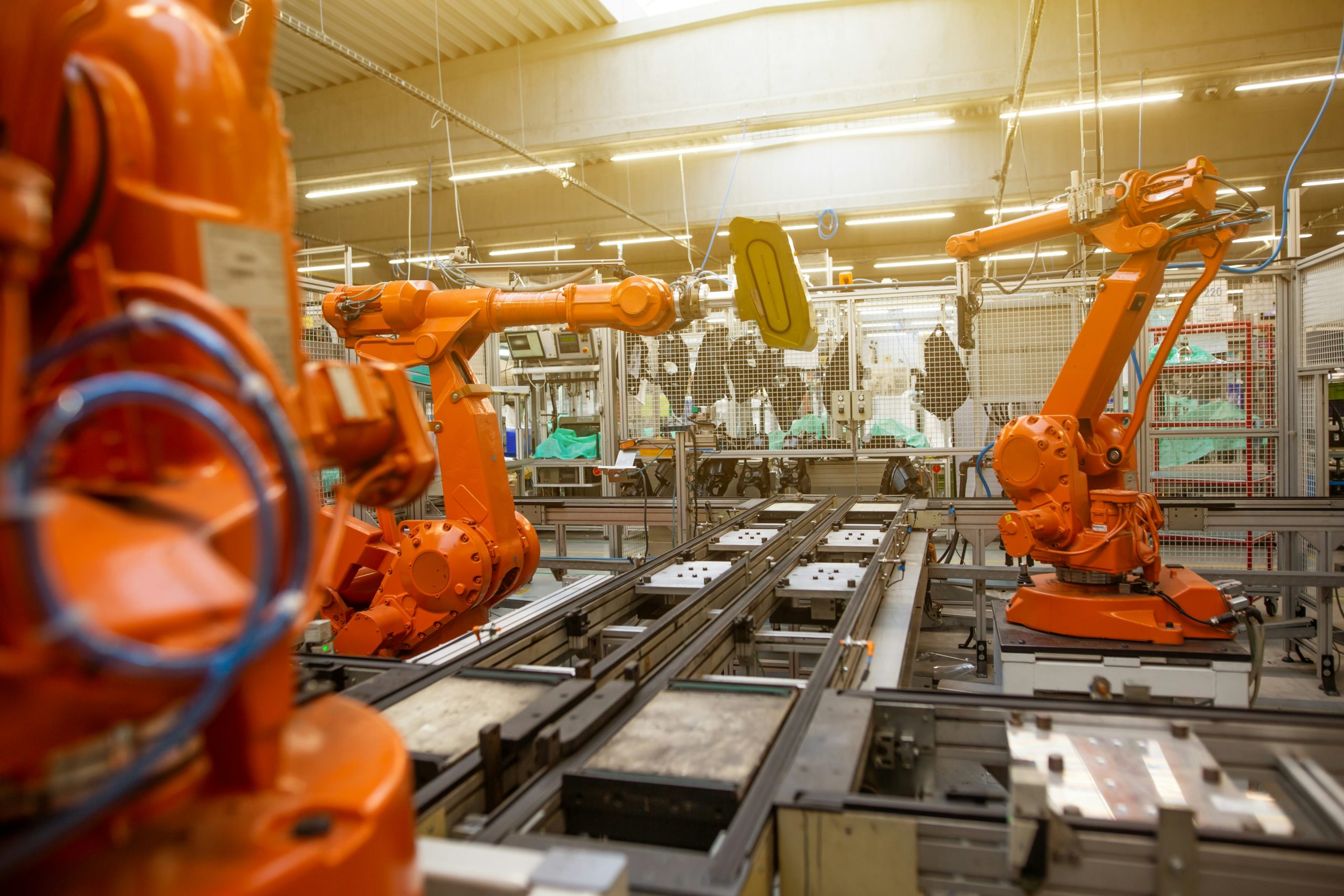

Machining centers are the backbone of many production lines. Ultra-precise, fast, and versatile, they make it possible to manufacture complex parts with high-quality standards. But

Redex Group integrates Lesly into its Smart Machine Pack for smarter rolling mills Redex’s Smart machine pack marks a new era in industrial maintenance. By

Industrial surveillance: a major challenge From March 11 to 14, 2025, EuroExpo Lyon (France) will be hosting Global Industrie, the leading event for players in

The industrial sector is rapidly evolving towards digital transformation, and SMEs must adapt to stay competitive. Connected monitoring optimizes machine maintenance, boosts productivity, and reduces

Industry faces a dual challenge: improving productivity while reducing environmental impact. To meet these challenges, companies are adopting advanced technological solutions such as predictive maintenance,

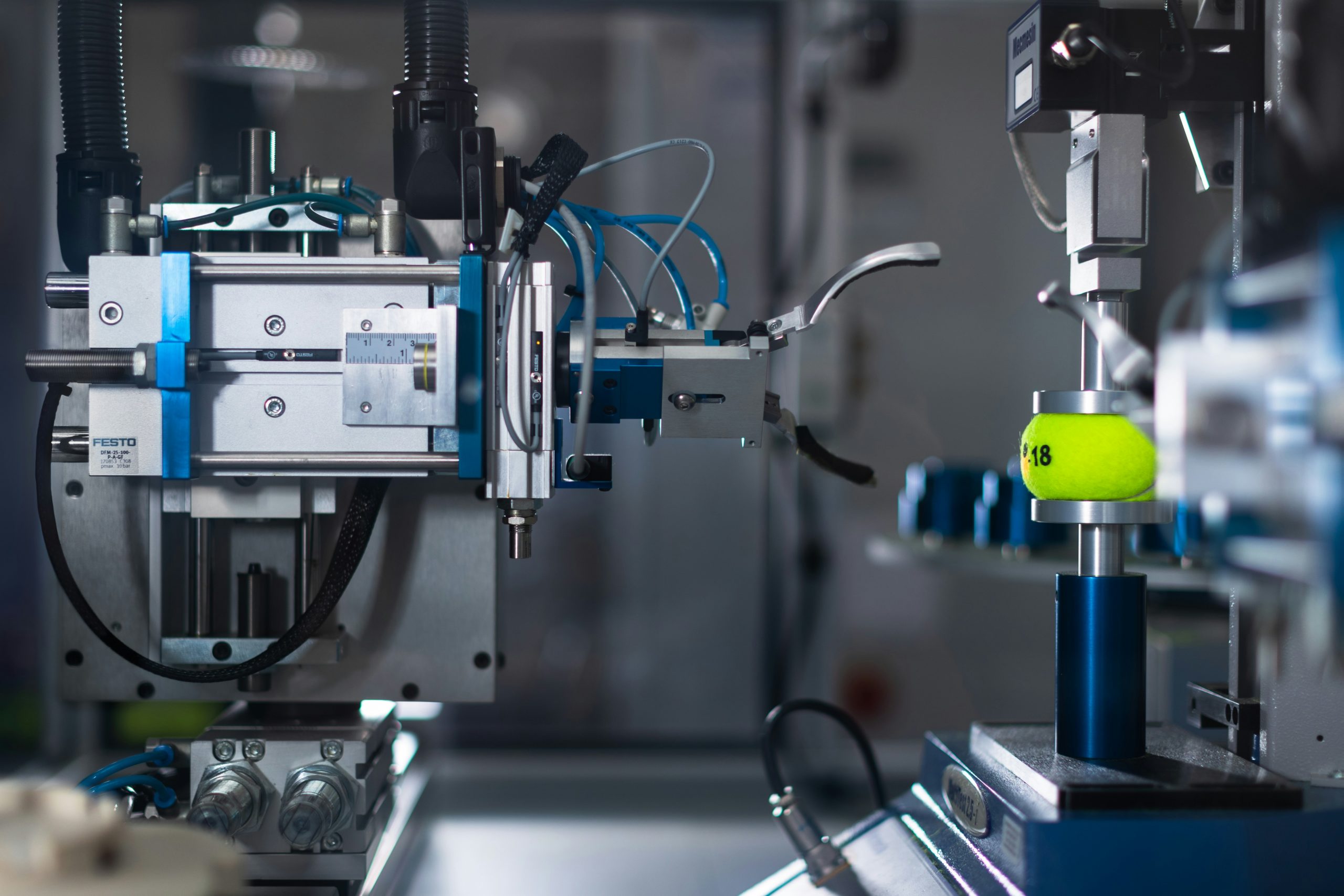

In industry, predictive maintenance is essential to guarantee the performance of machine tools. This equipment, often used in demanding sectors such as aerospace, automotive and

Machine downtime is one of the major challenges facing industry. With its direct impact on productivity and profit margins, it is a crucial concern. In

In the industrial world, optimizing performance and reducing unplanned downtime are major challenges. Thanks to our robust platform, which combines multi-source data collection, secure storage

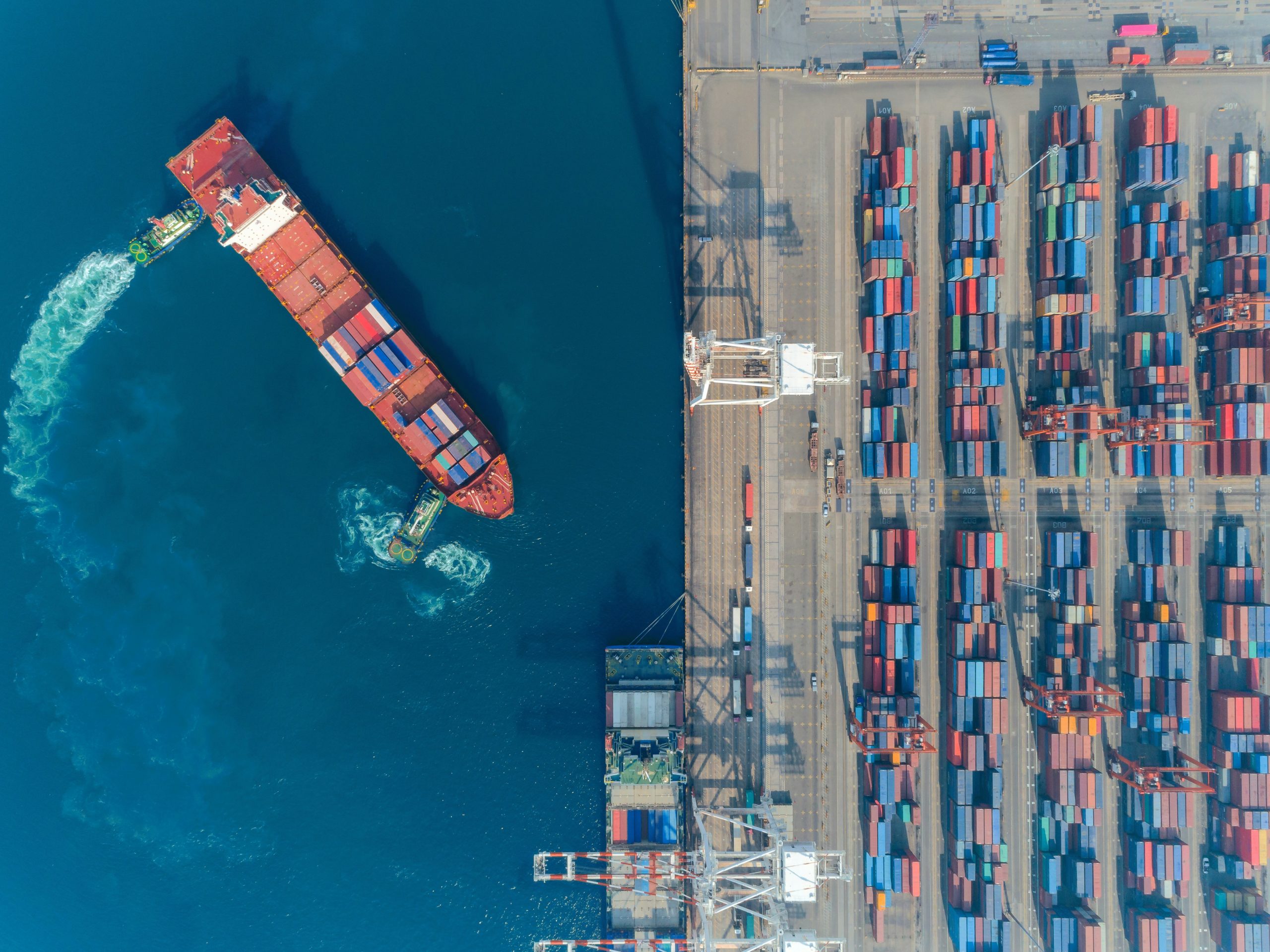

In a world where speed, efficiency and precision dominate, Big Data is transforming logistics. Thanks to data analysis, companies can optimize their processes. One area