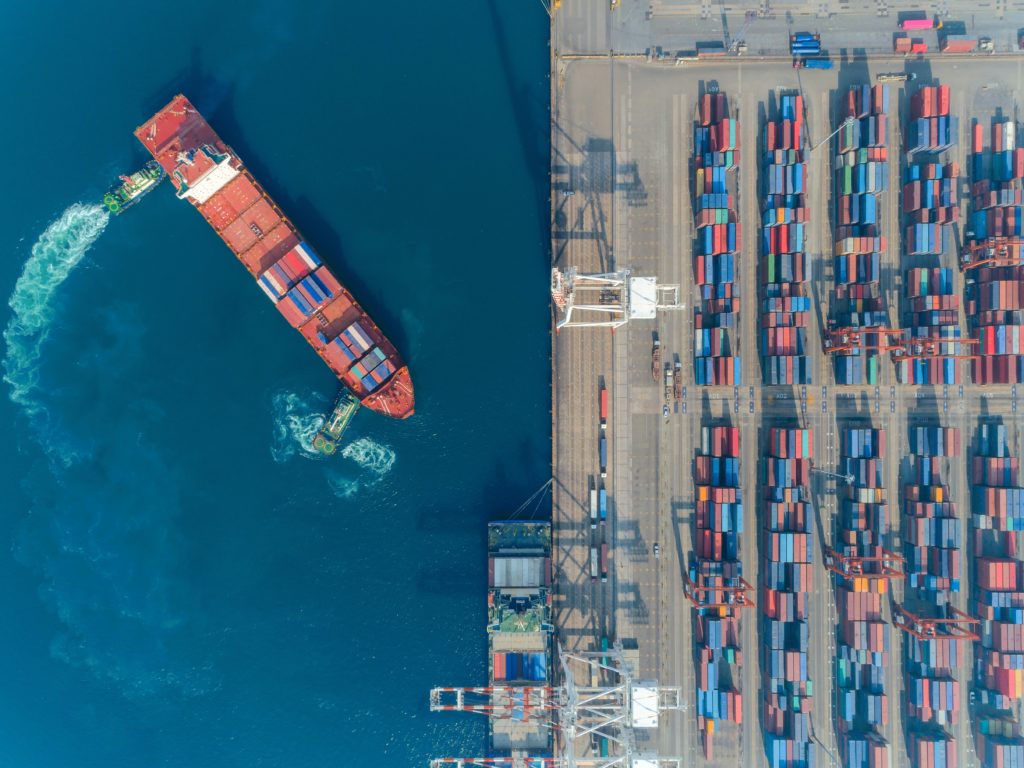

In a world where speed, efficiency and precision dominate, Big Data is transforming logistics. Thanks to data analysis, companies can optimize their processes. One area where this is essential is machine maintenance, ensuring uninterrupted operations. Big Data in logistics isn’t just about processing information, it’s about overhauling practices and driving continuous improvement.

Big Data in logistics: a major transformation

1. Optimizing logistics operations

Data collection improves every stage of the supply chain. Delays, routes and stock levels are analyzed to maximize efficiency. Predictive analysis based on advanced algorithms helps anticipate needs and optimize available resources.

- Dynamic planning: Big Data predicts fluctuations in demand, thereby adjusting resources. For example, companies can better manage seasonal peaks by adapting their deliveries.

- Real-time tracking: IoT sensors provide instant data, minimizing disruption. This makes it possible to monitor the location of goods and react quickly to unforeseen events.

By integrating these technologies, companies can reduce costs while increasing their responsiveness to logistical contingencies.

2. Machine maintenance: a key role

Machines are vital in modern warehouses. A breakdown can lead to high costs. Big Data in logistics anticipates and prevents these problems. Data from equipment enables innovative approaches to maintenance.

- Early detection: Sensors collect data on vibrations or temperatures, signalling anomalies. For example, an abnormal spike in vibration may indicate a bearing problem.

- Cost reduction: Preventing emergency repairs limits unnecessary expenditure. As unplanned breakdowns are costly, this approach optimizes maintenance budgets.

- Conditional maintenance: By analyzing data in real time, technicians can intervene before a breakdown occurs. This avoids prolonged downtime and maximizes equipment availability.

- Performance measurement: Data tracks machine efficiency, identifying opportunities for improvement. This enables companies to maximize the lifespan of their assets, while increasing overall productivity.

These practices not only ensure better continuity of operations, but also increase the reliability of logistics infrastructures.

The real benefits of Big Data

Increased responsiveness: Problems are detected and resolved quickly, minimizing the impact on supply chains.

Informed decisions: Data guide necessary investments and adjustments. Managers can accurately assess the costs and benefits of interventions.

Maximum efficiency: Reducing interruptions improves resource allocation. This enables efforts to be concentrated on high value-added activities.

Enhanced productivity: Continuous analysis optimizes machine utilization. This translates into lower operating costs and higher yields.

Big Data in logistics is a real catalyst for innovation, guaranteeing measurable and sustainable results.

Key statistics on Big Data in logistics

Market size: By 2023, the market had reached $4.3 billion, and is growing at 21.5% annually through to 2032. This growth illustrates the rapid adoption of these technologies.

Massive adoption: 98% of logistics companies are already using Big Data to grow. This testifies to its strategic importance in the sector.

Predictive maintenance: automated systems identify needs early on, avoiding unscheduled downtime. This approach also improves customer satisfaction thanks to more reliable deliveries.

These figures show that Big Data is now essential to remain competitive in a constantly evolving market.

Case study: Amazon and DHL

Leaders like Amazon harness Big Data to monitor machines. Their advanced algorithms detect anomalies, ensuring maximum efficiency even during periods of high demand. DHL, meanwhile, uses similar technologies to optimize its logistics hubs and delivery routes. These examples perfectly illustrate how Big Data in logistics can transform practices and boost performance.

Conclusion: Smarter logistics thanks to Big Data

Big Data in logistics is revolutionizing operations, particularly in maintenance. By investing in these technologies, companies are boosting their competitiveness, improving productivity and enhancing customer satisfaction. As the market continues to grow, integrating these solutions becomes essential to stay ahead. Companies that adopt these tools today will be better positioned to meet tomorrow’s logistics challenges.