Using AI to Predict Industrial Failures

In an era where competitiveness relies heavily on the reliability and responsiveness of equipment, using AI to predict industrial failures has become a strategic necessity. By analyzing machine data in real time, solutions like LESLY, developed by Dianalyse, help avoid unplanned downtime, extend component lifespan, and optimize maintenance with unprecedented precision. Why the Industry Is […]

Connected Monitoring: Why SMEs Should Invest Now

The industrial sector is rapidly evolving towards digital transformation, and SMEs must adapt to stay competitive. Connected monitoring optimizes machine maintenance, boosts productivity, and reduces operational costs. Yet, 80% of industrial failures could be prevented with intelligent equipment monitoring. So, why wait? Machine Downtime: A Costly Issue for SMEs Every production stoppage represents a significant […]

Predictive Maintenance: A Lever for Sustainable Industry

Industry faces a dual challenge: improving productivity while reducing environmental impact. To meet these challenges, companies are adopting advanced technological solutions such as predictive maintenance, which optimizes equipment utilization and limits the waste of resources. By extending machine life and reducing energy consumption, this approach is fully in line with sustainable industry. Sustainable industry: a […]

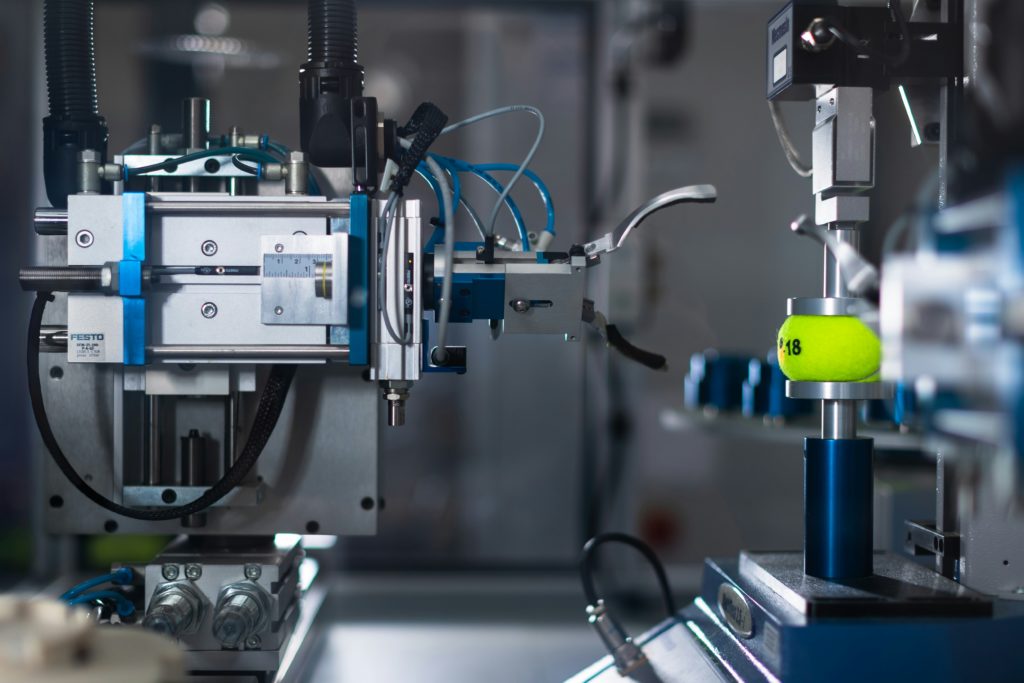

Predictive Maintenance: Optimize Your Machine Tools with Lesly

In industry, predictive maintenance is essential to guarantee the performance of machine tools. This equipment, often used in demanding sectors such as aerospace, automotive and nuclear power, represents a major investment, sometimes in excess of one million euros. To maximize their return on investment, efficient maintenance management is essential. This is where Lesly comes in, […]

Machine downtime: how to boost industrial productivity?

Machine downtime is one of the major challenges facing industry. With its direct impact on productivity and profit margins, it is a crucial concern. In this article, we detail its causes, costs and effective strategies for minimizing it. What is machine downtime? Machine downtime refers to periods when production equipment is at a standstill. This […]

Industrial Machine Monitoring: robust architecture

In the industrial world, optimizing performance and reducing unplanned downtime are major challenges. Thanks to our robust platform, which combines multi-source data collection, secure storage and advanced analysis, industrial machine monitoring is more reliable than ev Solid Architecture for Optimal Supervision The robustness of our solution is based on an innovative and adaptable technical infrastructure. […]

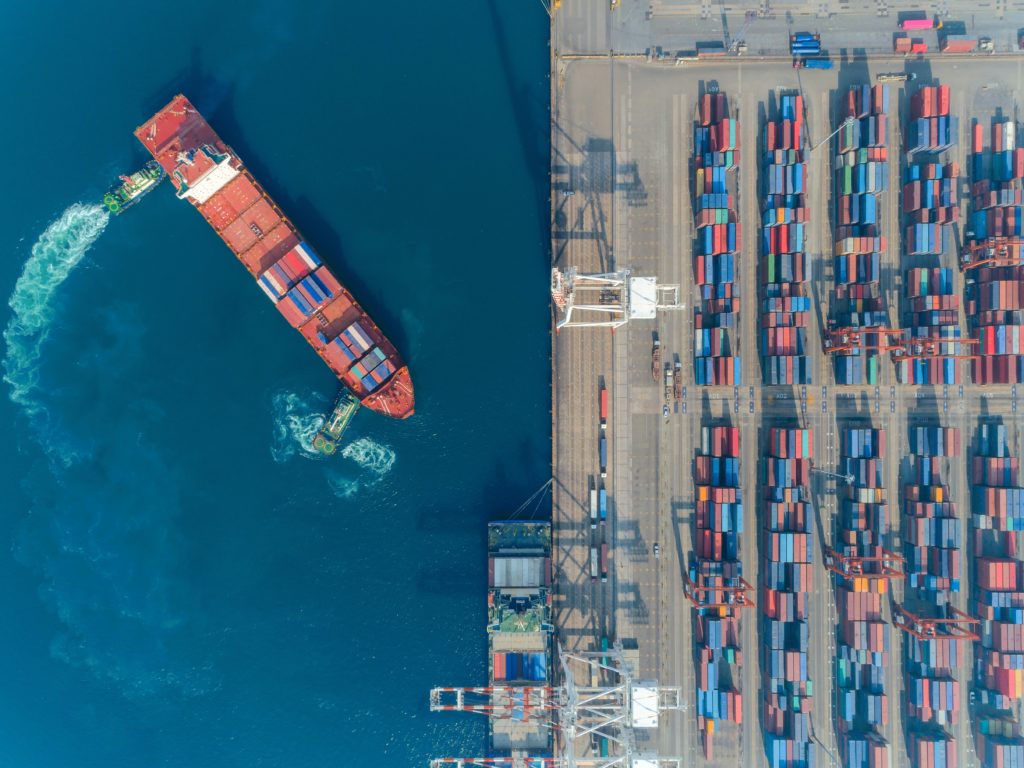

Logistics revolution: the power of Big Data

In a world where speed, efficiency and precision dominate, Big Data is transforming logistics. Thanks to data analysis, companies can optimize their processes. One area where this is essential is machine maintenance, ensuring uninterrupted operations. Big Data in logistics isn’t just about processing information, it’s about overhauling practices and driving continuous improvement. Big Data in […]

Best practices for machines in the aerospace industry

Maintenance for machines in the aerospace industry is crucial to ensuring safe, reliable and profitable operations. With global spending on maintenance, repair and overhaul (MRO) reaching $67.6 billion in 2016, and the market constantly expanding, proactive machine management is becoming a top priority for companies in the sector. Here are some concrete solutions for optimizing […]

Food Industry Maintenance: Optimize with Machine Monitoring

Here’s a shorter version: “Food Industry Maintenance: Boost Performance with Machine Monitoring” The food industry, a cornerstone of the economy, is evolving rapidly to tackle major challenges: increasing volumes, adhering to strict standards, and maintaining product quality. In this context, machine monitoring has become an essential solution to optimize food industry production, enhance yields, and […]

Why machine performance monitoring is essential in 2024

In 2024, machine performance monitoring has become crucial for industrial companies in their quest for efficiency and competitiveness. With technological advances, it is now possible to collect and analyze data in real time for complete visibility of equipment operation. This article explores why this monitoring has become a strategic priority for optimizing production, reducing costs, […]